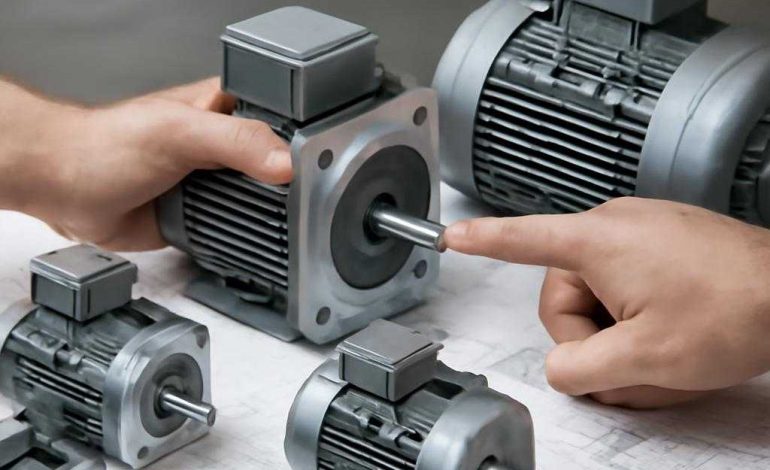

Selecting industrial drives with precision

I’ve worked with a range of industrial drives and can attest that selecting reliable components makes a real difference; when researching options, I often consult suppliers of electric motors to compare specs, support and documentation before committing to a purchase.

Practical checks before you buy

If you’re planning an upgrade, you should evaluate a few concrete factors to avoid surprises. Look at duty cycle, environmental exposure and spare-part availability; for many end users the choice of a supplier of electric motors also determines how quickly faults can be resolved. Consider these points:

– Match the motor’s continuous and intermittent ratings to your actual load.

– Check IP rating and insulation class if dust, moisture or heat are present.

– Confirm that local service and replacement parts are available.

Be encouraged: a well-matched drive reduces energy use and mechanical wear, improving uptime. On the flip side, be cautious — a decision driven only by lowest price often leads to higher lifecycle costs.

They (the installation teams) typically follow a phased approach to mitigate risk, which looks like this in practice:

1. Run a pilot installation to gather real operational data.

2. Adjust settings and protections based on measured behavior.

3. Roll out the full installation with a defined maintenance schedule and operator training.

For product details, datasheets and vendor contact information, check the supplier’s portal at https://vyboelectric.co.za/. Making informed, measured choices today will save you time and money tomorrow.